|

|

Apparently this idea originally came from Pete "Banjo Doctor" Wernick. Thanks Doc!

In my opinion the first step is to become used to using fresh picks – that is – that do not have too much wear on the tip (see diagram below). They're so cheap compared to your banjo so buy a box full. If there is more length in your thumb pick, you won't need to dig so deep. This could resolve your problem right here!

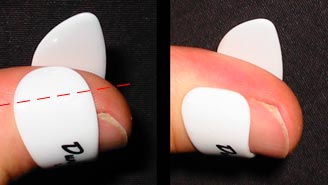

The specific problem I'm talking about is when the thumb pick "hooks" one of the strings. This is extremely annoying and hard to cover up if you are playing in front of an audience. Below is a picture of what I'm describing.

Have a cup full of boiling water ready, then grab the end of the pick that wraps around your thumb with a pair of pliers — right on the tip so you only alter the end.

Note: make sure the pliers do not have teeth (grip) otherwise the teeth marks will make imprints into the pick when it becomes soft, resulting in a rough surface. Then dip the pick into the water until it becomes soft enough to bend the plastic.

An idea I tried today which is a bit more fiddly, but ensures a neater bend, is to press a hard surfaced flat object (such as the side of a bread knife) against the edge. When the pick is soft you can curl the edge around without worrying about any unwanted angles that you may get with pliers. You want a bend that is parallel to the strings otherwise they may catch on the edges. Remember, the edge bending trick works well if you do it properly, but if you do a sloppy job you'll still catch the strings and find it even harder then before to dislodge the string.

Finally, I smoothed down the edges with an emery board to ensure the strings wouldn't catch on the striking side of the pick.

Another way of dealing with the problem is to remove it completely. I tried this and found it to be more effective then moulding the pick – less time consuming too.

You can see in the diagram above where I've cut the plastic. The easiest way to do it is to put the pick over a rounded peice of dowel with one end firmly secured in a vice. Then carefully cut the tip off with a coping saw. You don't want to cut too much off or the pick loses it's strength. I've found that cutting this much off doesn't effect the stability when I'm picking.

In the comparison below you can see the pick before and after.